Today we will be giving you a tour of how we make one of our most popular products! Tiny Blanks!

Today we will be showing you how we cut one of our most popular products and top sellers. Tiny metal blanks, they are cut using a progressive cutter. The results are tiny yet detailed shapes with super clean edges, this means they are perfect for designing jewelry.

Laura designed these tiny shapes for soldering onto stackable rings. She had the vision to realize how useful these tiny shapes would be for jewelry design! Many people prefer small or petite jewelry, and these blanks give depth and detail for that design style. Instead of sawing each tiny design by hand, Laura decided we needed a cutter to perfectly slice through the sheet metal! Previously it was a tedious and difficult task to saw something so tiny, but we have found the best way to save time (and saw blades!)

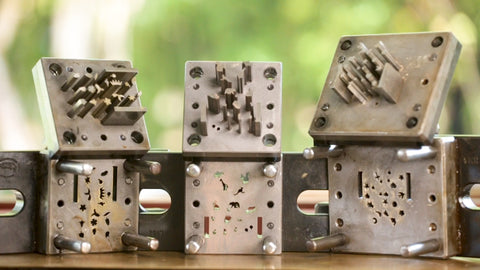

This is a progressive cutter, Not many people create these cutters as they are difficult and complicated to produce. Each cutter may have up to 18 shapes at the end of long tempered steel rods, these are cut with our designs. Below the rods is a thick plate of tempered steel, each rod has a perfectly matching hole, the plate is where the cutting of the metal really happens. These are super precise!

Pedro is in charge of our big machine workshop. In 12 years he has learned everything! We are really proud of him and feel lucky to have such an intelligent and capable person in charge of such specialized tools. With every new tool Pedro has managed to learn or teach himself everything necessary to use and maintain the equipment. Plus he is continually learning more as we develop new products. Around SupplyDiva Pedro is the clown of the team, he always has a smile for everyone, and more often than not a joke to get everyone laughing! Sometimes he even plays tricks on us and we have to run him off to his own workshop. We all think highly of him and we care a great deal about him and his family.

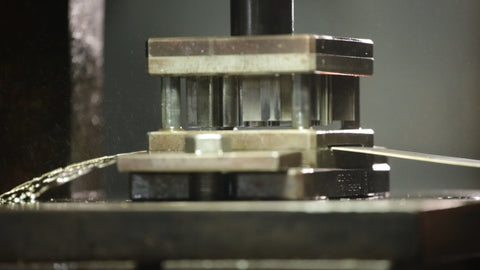

Each cutter is installed into a 12 horse powered machine. When we install the Progressive Cutter into the machine it has to be perfectly centered so the four outside rods that hold the whole thing together can slide up and down perfectly. The rods with our designs are rather delicate because they are so thin and tiny, this means they are prone to breakage and damage. If one does break we can have the shape remade and replaced, or we can decommission that shape and continue using the cutter. Due to the delicacy of the individual cutters, only 24 gauge metal can be used. And each cutter must be sprayed with WD-40 upon every use this lubricates the cutters and ensures good contact and movement.

Once the sheet is cut to the size of the cutter, we are ready to begin feeding the sheet into the machine. As the sheet moves along, the cutter may make multiple cuts to the same shape to give it its detail. The cutter will continuously cut grooves on the edges of the sheet of metal, thus it is able to grab the sheet and move it forward the correct distance. This ensures that each cut happens in the correct location.

Now we must sort through what's been cut, there will be scrap, extra pieces cut on the edges of the sheet, these must be separated from the finished tiny shapes before they get a light tumbling to clean off the oils from the cutter and lightly smooth the edges. The finished tiny shapes are perfect. The edges are clean and free of burrs. Each one is perfectly detailed.

Jewelry design becomes easy with these tiny blanks. Solder on posts for stud earrings. Solder them onto a ring band and create a set of stackable rings. Solder them onto your pendants or bracelets. The copper and fine silver versions work for copper enamel and lampworking. We have also used them in our resin jewelry. We hope this video has inspired you to get crafty and we hope you will enjoy making jewelry with our tiny shapes! Please feel free to let us know if you have any requests for tiny designs, we are always working on new cutters!